UNS: S32100 / S32109 | W. Nr: 1.4541 / 1.4878 | EN: X6CrNiTi18-10 / X8CrNiTi18-10

321 / 321H

321 and 321H stainless steel are titanium-stabilized austenitic stainless steels developed to provide improved resistance to intergranular corrosion after exposure to temperatures in the chromium carbide precipitation range (800–1500°F). These grades are ideal for high-temperature applications where welding is required.

Key Features

- High-Temperature Strength: Excellent performance in temperatures up to 900°C (1652°F).

- Intergranular Corrosion Resistance: Titanium stabilization prevents carbide precipitation.

- Weldability: Suitable for welding without post-weld annealing.

- Structural Integrity: Maintains mechanical properties under thermal cycling.

Industries and Applications

321 / 321H stainless steel is commonly used in:

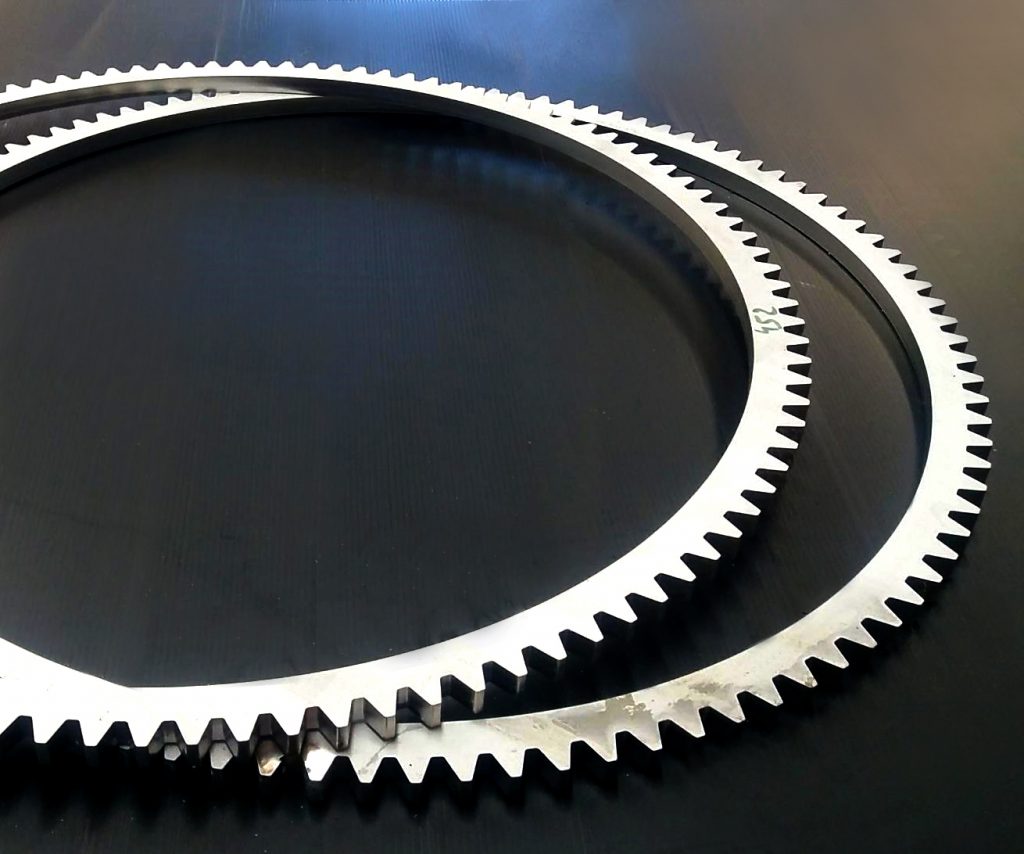

- Aerospace: Jet engine components, exhaust systems

- Heat Treatment Equipment: Furnaces, radiant tubes

- Chemical Processing: High-temperature piping and tanks

- Automotive: Manifolds, turbocharger components

- Construction: Expansion joints, structural supports

Difference Between 321 and 321H

- 321H has a higher carbon content, offering enhanced creep resistance and strength at elevated temperatures.

- 321 is preferred for general high-temperature service, while 321H is ideal for pressure vessels and structural components exposed to sustained heat.