UNS: S41000 | W. Nr: 1.4006 | EN: X12Cr13

410

410 stainless steel is a hardenable, martensitic stainless steel known for its high strength, moderate corrosion resistance, and excellent wear resistance. It is commonly used in applications requiring good mechanical properties and mild corrosion resistance, especially where heat treatment is required for added hardness.

Key Features

- High Strength & Hardness: Can be heat treated to achieve high mechanical strength and wear resistance.

- Moderate Corrosion Resistance: Performs well in mildly corrosive environments.

- Machinability: Good machinability in the annealed condition.

- Heat Treatable: Can be hardened through quenching and tempering.

Industries and Applications

410 stainless steel is ideal for:

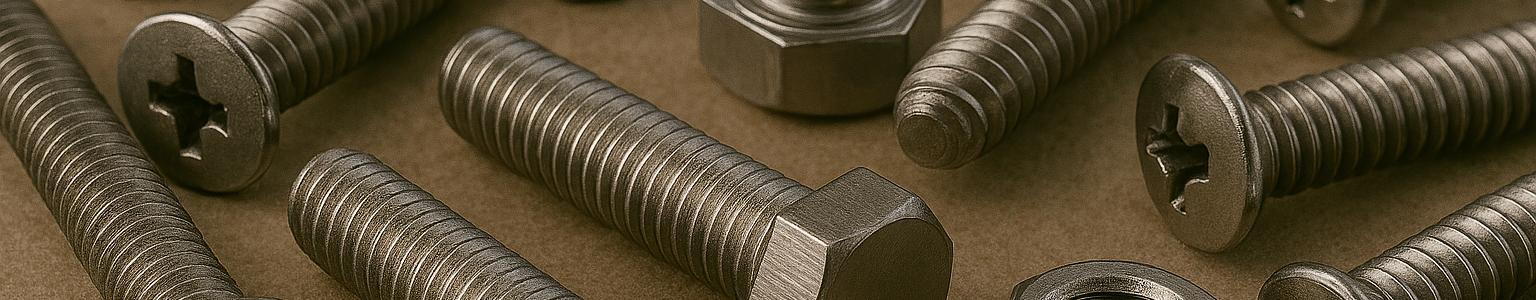

- Fasteners: Screws, bolts, and nuts

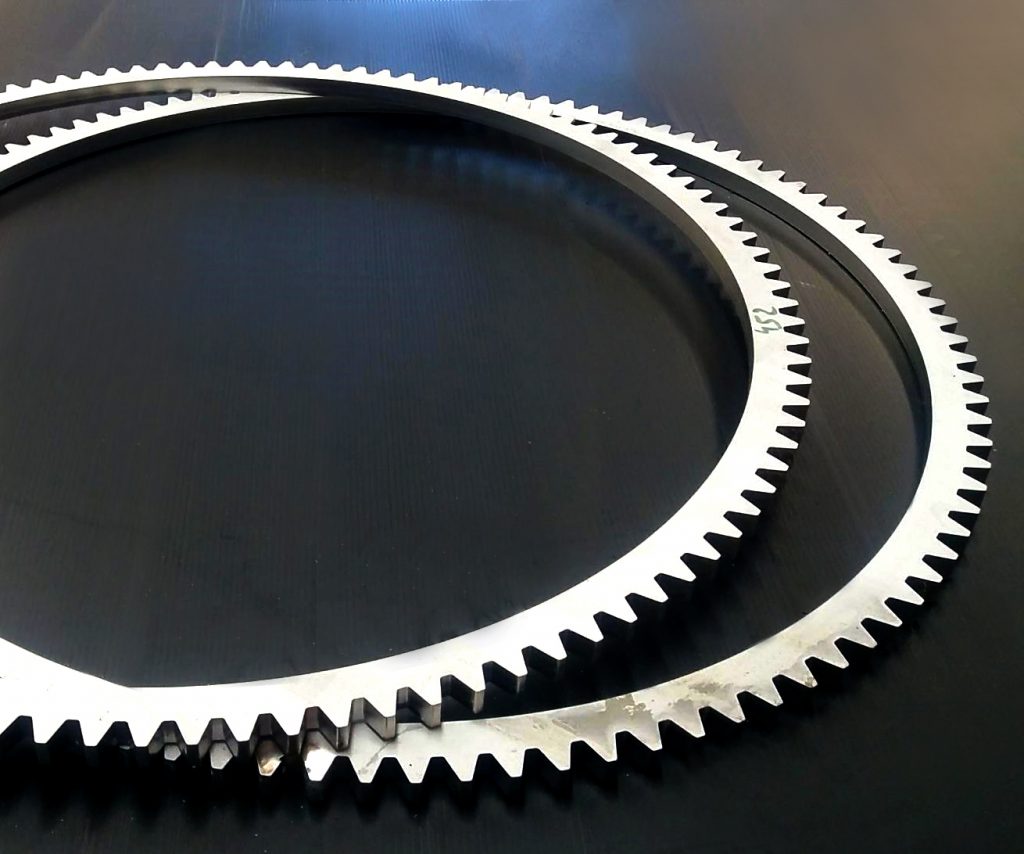

- Mechanical Parts: Shafts, bushings, gears

- Cutlery & Tools: Knife blades, surgical instruments

- Automotive: Valve components, exhaust parts

- Industrial Equipment: Pumps, valves, and wear-resistant parts

Heat Treatment & Aging

- Supplied in solution-annealed condition (Condition A).

- Can be hardened by precipitation heat treatment to various conditions (H900 to H1150).

- Offers a balance between strength, ductility, and corrosion resistance depending on the chosen condition.