Using our extensive cutting capacities (plasma, laser, waterjet, and sawing), we can guarantee our clients high-quality products with tight tolerances and delivered in a fast and reliable time frame.

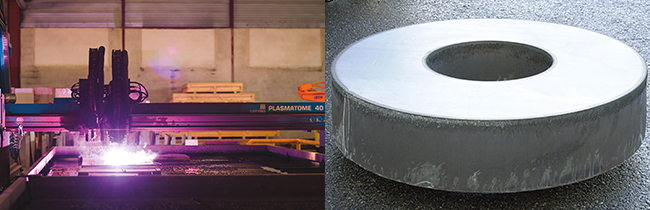

The most economical solution for all forms of stainless steel and nickel alloy pieces.

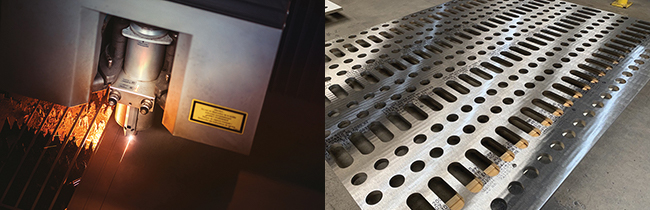

The high precision of the laser allows tight tolerances up to 2″ thickness. Also ideal for large quantities of pieces.

High-pressure waterjet cutting reduces or avoids possible machining. No shape or thickness limitations, cold cutting without heat affected zone (HAZ). Ideal for complex cutting of stainless steels and nickel alloys.

Sawing ensures a good cutting perpendicularity for medium and thick pieces and flats, without a heat affected zone (HAZ).

Compare tolerances according their cutting processes

| PLATE SAW | |||

|---|---|---|---|

| 79″ x 240″ max size | |||

| THK | Standard | Premium | Best |

| 1.0″ <= 2.50" | + .125″/-0″ | +/- .0625″ | +.0625″/-0″ |

| >2.50″ <= 4.00" | +/- .125″ | +/- .0625″ | +.0625″/-0″ |

| >4.00″ <= 6.00" | +/- .1875″ | +/- .125″ | +/-.0625″ |

| BAR SAW | |||

|---|---|---|---|

| Max. Dia. 18″ | |||

| Diameter | Standard | Premium | Best |

| <=10" | +/- .125″ | +/- .0625″ | +.0625″/-0″ |

| >10″ | +/-.1875″ | +/-.125″ | +.125″/-0″ |

| BYSTRONIC LASER 30KWH | |||

|---|---|---|---|

| 100″ x 240″ max size | |||

| THK | L ≤ 12″ | 12″ < L ≤ 36" | L > 36″ |

| ≤ 0.375″ | ± 0.015″ | ± 0.032″ | ± 0.0625″ |

| > 0.375″ ≤ 0.75″ | ± 0.023″ | ± 0.040″ | ± 0.072″ |

| > 0.75″ ≤ 1.125″ | ± 0.043″ | ± 0.060″ | ± 0.092″ |

| 1.25″ ≤ 2″ | ± 0.0625″ | ± 0.0625″ | ± 0.0625″ |

| WATERJET | |||

|---|---|---|---|

| 120″ x 315″ max size | |||

| THK | Standard | Premium | Best |

| .1875″ <= 2.50" | +/- .0625″ | +/- .03125″ | +.032″/-0″ |

| >2.50″ <= 4.00" | +/- .125″ | +/- .0625″ | +/- .03125″ |

| >4.00″ <= 6.00" | +/- .1875″ | +/- .0625″ | +.0625″/-0″ |

| No common cuts on bevel head | |||

| Bevel | 0°-59° | ||

| Max Thk. | 4″ | ||

| Max Width | 96″ | ||

| Max Length | 300″ | ||

| Bevel Tolerance | +/- 1° | ||

| PLASMA | ||||||

|---|---|---|---|---|---|---|

| 156″ x 500″ max size | ||||||

| THK | Standard | |||||

| .1875″ <= 1.50" | +/-.0625″ | |||||

| >1.50″ <= 2.00" | +/-.125″ | |||||

| >2.00″ <= 4.00" | +/-.25″ | |||||

| >4.00″ <= 6.00" | +/-.375″ | |||||

| Bevel | 0°-59° | |||||

| Max Thk. | 4″ | |||||

| Max Width | 120″ | |||||

| Max Length | 480″ | |||||

| Bevel Tolerance | +/- 2° | |||||